A panel saw is a specialized machine used in woodworking and manufacturing to accurately cut large sheets of materials such as plywood, MDF, melamine, plastic, and even metal into smaller, usable parts. The main advantage of a panel saw is its ability to deliver precise and straight cuts, which is essential for industries like cabinetry, furniture making, sign manufacturing, and construction.

There are two main types of panel saws:

- Vertical panel saws: These hold the material upright, making them a space-saving choice. In lower-cost models, the user manually slides the material through the saw for lengthwise (rip) cuts, while higher-end models allow the blade itself to move through the stationary material for greater precision.

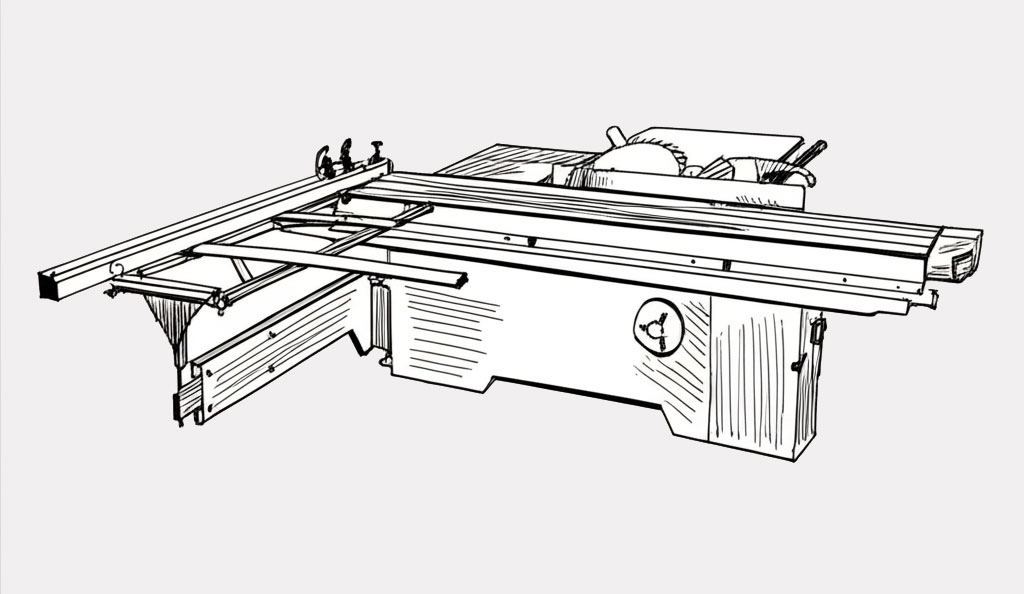

Horizontal panel saws: These feature a sliding feed table that pushes the material through the blade. They are preferred for high-volume production environments because they tend to be faster and often allow for more automation.

Some panel saws include extra features such as scoring blades to prevent material chipping, and advanced models may be computer-controlled (CNC) for increased accuracy and automation. Their adaptability allows them to cut different materials depending on the blades used and the requirements of the specific application.

In summary, a panel saw is a cornerstone tool wherever there is a need to cut large panels into precise, manageable pieces efficiently and safely.